An Overview of Proper Gas Turbine Maintenance

Regular maintenance is paramount for ensuring the optimal performance and longevity of gas turbines. It helps in the prevention of unexpected breakdowns and avoiding costly downtime by addressing potential issues. Keeping the turbine in proper working condition ensures it operates at optimal performance levels.

Efficiently operating turbines consume less fuel for a given power output, thus reducing energy waste and fuel consumption. Regular maintenance activities contribute to an optimal heat rate, a measure of efficiency in converting fuel to electricity, and extend the equipment's life. Safety inspections also help with reducing the risk of accidents.

How to Improve Gas Turbine Efficiency

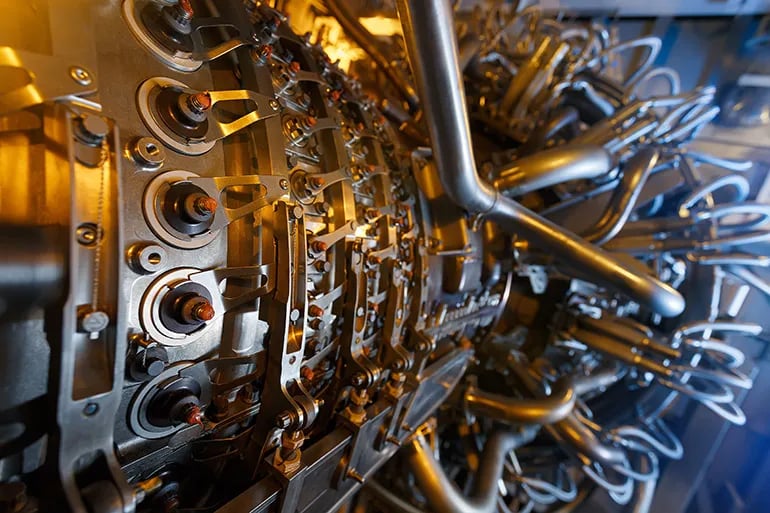

This complex task involves a series of planned and preventive activities, such as inspections, cleaning, lubrication, and part replacements.

- Inspections are key in identifying potential issues before they escalate, focusing on critical components like compressor blades, combustion chambers, and turbine rotors.

- Cleaning is equally important, removing dirt, dust, and debris to maintain optimal airflow and heat transfer efficiency.

- Lubrication reduces friction and wear which is vital for smooth operation.

- Over time, parts like blades, seals, turbine rings, filters, and sensors may require replacement. These scheduled maintenance intervals are crucial to prevent unexpected breakdowns and ensure the turbine's efficient operation.

Key Factors That Affect Gas Turbine Efficiency

- Air Intake Temperature: Warmer air reduces the density and mass flow rate through the turbine, leading to lower power output and efficiency.

- Compressor Efficiency: A well-maintained and optimized compressor ensures proper air flow and pressure ratios, crucial for turbine performance.

- Turbine Blade Condition: Erosion, corrosion, or fouling of blades can negatively impact efficiency.

- Fuel Quality: The efficiency of combustion can be compromised by impurities in the fuel or suboptimal fuel-to-air ratios.

- Control System: A well-functioning control system continuously adjusts various parameters like fuel flow and power output for maximum efficiency.

- Maintenance Practices: Regular cleaning, lubrication, and inspection are key to maintaining peak efficiency.

Gas Turbines vs Steam Turbines - How Do They Compare?

There are several differences between gas turbines vs steam turbines. Steam turbines generally have higher efficiency compared to gas turbines, mainly due to the higher pressure and temperature conditions in steam turbines.

Gas turbines require components like a compressor and combustion chamber. Steam turbines need a steam boiler and heat exchanger. Gas turbines are typically more cost-effective, requiring less space and installation. Steam turbines usually require additional space and higher running costs.

How Can St. Marys Carbon Help with Turbine Efficiency?

Our HALO™ turbine and compressor rings are instrumental in improving the efficiency of gas turbines. Constructed from premium carbon graphite, these rings stand out due to their ability to withstand high temperatures and their low friction and wear characteristics, attributed to their self-lubricating nature.

These features notably lower the risk of failures and facilitate their adaptability to multiple settings. The versatility of our carbon graphite compressor rings extends to a myriad of products and industries. To cater to the unique requirements of various applications, we offer specialized customization services. This enables the precise tailoring of these rings, ensuring they deliver optimal performance in every specific context they are used. Our approach ensures that each application benefits from a compressor ring that is perfectly suited to its individual needs.

FAQs about Gas Turbine Maintenance

What are the most common issues with gas turbines?

- Fouling and Erosion of Compressor Blades: This leads to reduced efficiency and airflow, impacting the overall performance of the turbine.

- Combustion Issues: Problems such as flame instability or incomplete combustion can arise, often due to fuel quality issues or improper fuel-to-air ratios.

- Bearing Failures: Bearings in gas turbines are subjected to high stress and can fail due to inadequate lubrication or excessive operational loads.

- Thermal Stress and Creep in Turbine Blades: Prolonged exposure to high temperatures can cause blades to deform or crack, affecting the turbine's efficiency and safety.

How efficient are gas turbines?

Gas turbine efficiency can vary from 20-40%.

Wrapping Up - Maximizing Efficiency with Proper Gas Turbine Maintenance

Gas turbine maintenance and optimization are critical for ensuring efficient and long-lasting operation. Regular maintenance, addressing factors such as air intake temperature, compressor efficiency, and the condition of turbine blades, plays a vital role in maximizing efficiency.

Incorporating sophisticated materials like carbon graphite grades into components like St. Marys Carbon's HALO™ turbine and compressor rings significantly boosts the efficiency of gas turbines. This enhancement, coupled with diligent maintenance practices, allows operators to markedly improve the turbines' performance and extend their operational lifespan. Such improvements render gas turbines increasingly viable and cost-effective for a range of industrial uses, optimizing their functionality and economic value in various applications.